Customer

As a global manufacturer of sophisticated test and measurement equipment based in Austria, our customer prioritizes precision and high-quality products. The calibration of measurement equipment, particularly emission testing benches, is crucial to meet industry standards such as Euro 6, CFR, US EPA, among others.

Challenge

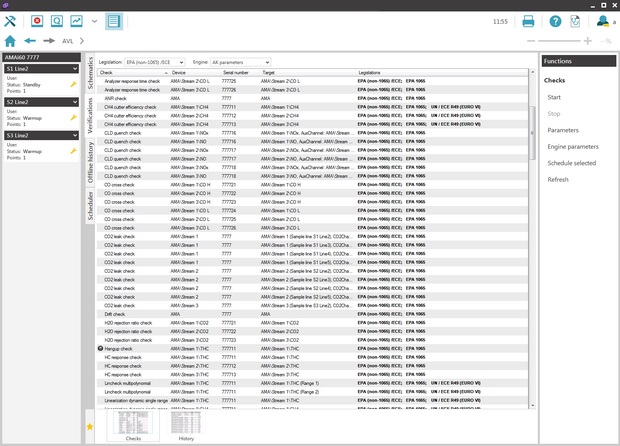

As a leading supplier to automotive industry giants, our customer faces the challenge of maintaining the precision and quality of its products. The manual calibration and checks of emission testing benches, each containing 5–8 gas analyzers, can take weeks or even months depending on the equipment. To overcome time-consuming operations, the client sought to automate the calibration process.

Solution

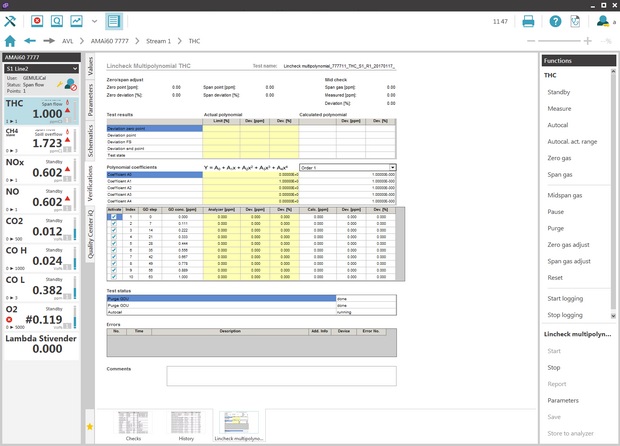

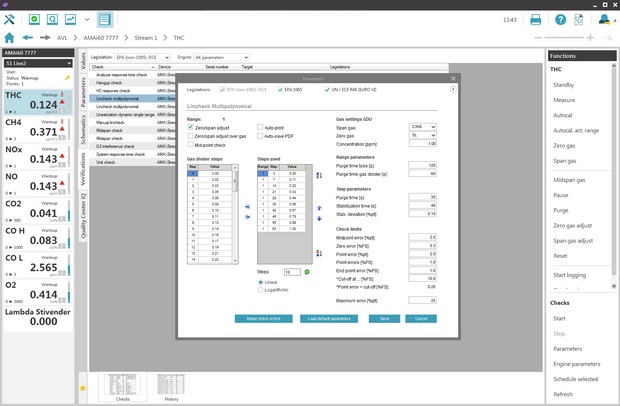

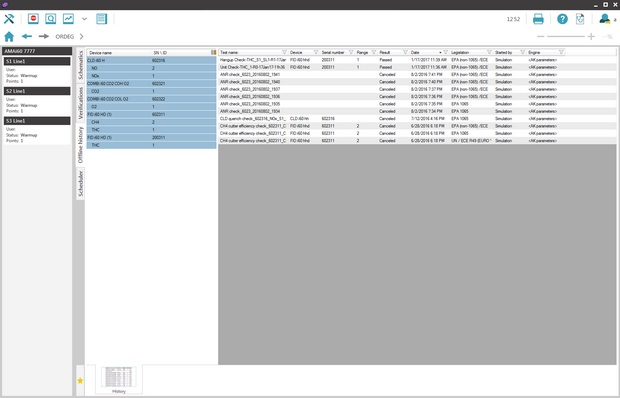

Applied Systems’ team developed an automated calibration system tailored to the client's needs. This system features graphical interfaces that allow users to parameterize checks, schedule launches, and manage procedures in a database seamlessly.

Results

The implementation of the automated calibration system has streamlined calibration and check operations for our customer. Users no longer need to handle parameter entry or data saving – the automated calibration system takes care of these tasks efficiently.

The impact of calibration automation software is evident in the accelerated certification of measurement equipment and reduced costs. On average, one automated gas measurement line now performs:

- 500 calibration operations annually;

- 250 hours of calibration;

- 80 types of checking and calibration operations;

- 1,000 pages of reports.

Scheduling checks has provided flexibility, allowing operations to run at any time, including overnight. Overall, calibration downtime has been minimized to just a few hours. Reports, generated swiftly according to standards, are securely archived in a database, offering the ability to restore them at any time or export into another database.