Customer

As a leading Austria-based manufacturer specializing in sophisticated engine, transmission, and emission testing systems, our customer serves various vehicles, including passenger cars, commercial vehicles, construction, and large engines. The complexity of their solutions, comprising comprehensive multi-component engineering systems, necessitates intricate customization for each end client.

Challenge

The meticulous configuration of emission testing benches, integral to the automotive industry, posed a significant challenge. Each unit sold required adaptation to the precise requirements of the end client. Manual configuration of these elaborate setups, with over 10,000 diverse parameters, proved time-consuming and error-prone. The primary challenge was to devise a solution that could automatically generate and execute configurations for the controlled equipment.

Solution

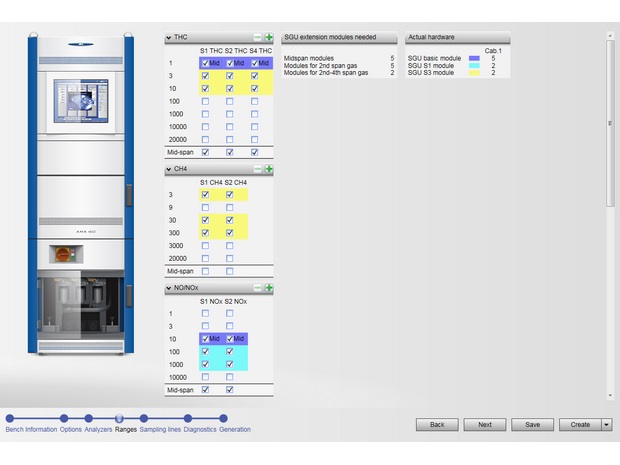

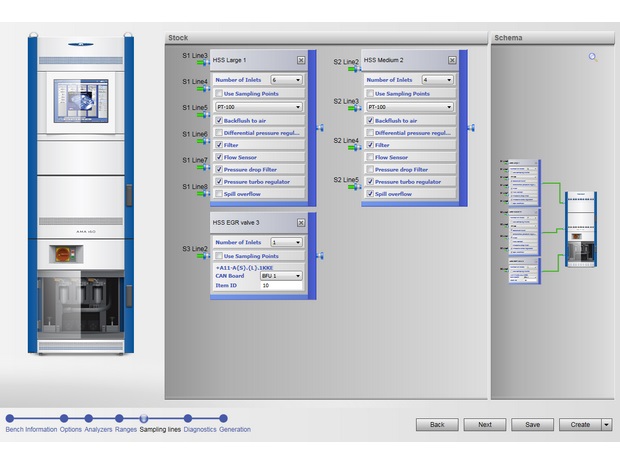

Applied Systems introduced a Configuration Manager, simplifying the process dramatically. With minimal input data from the user, the software automatically adjusted most parameters, requiring users to enter only high-level information defining the hardware configuration requirements.

The team developed a comprehensive program model capturing the complete configuration based on user input, outlining high-level usage scenarios in successive steps. The Configuration Manager employed over 30 independent generation algorithms for specific aspects of configuration, such as gas schemes, electrical wiring, and bench environment settings. It also automatically generated user interface panels, including operation panels, gas flow diagrams, and service control panels.

Apart from generation algorithms, the system incorporated validation and verification algorithms to ensure the correctness of the created configurations. Applied Systems collaborated closely with the client's experts, engaging stakeholders from various departments to review specifications and incorporate their feedback into the project documentation.

The first stable version of the software was released in a remarkable four months. Notably, the system's open architecture allows seamless integration with equipment upgrades, enabling continuous improvements in the Configuration Manager as it gains expertise in handling various equipment types.

Results

Applied Systems' configuration software led to remarkable improvements in equipment configuration creation. What used to take several days can now be completed within a few hours, thanks to the Configuration Manager's automation technology. The client experienced enhanced efficiency and accuracy, empowering them to provide exceptional emission testing systems to their customers effortlessly.

By streamlining the configuration process, the software proved to be a powerful configuration solution in industrial automation, saving valuable time and resources for the client and yielding precise results in their emission testing endeavors.

The Configuration Manager exemplifies Applied Systems' commitment to providing cutting-edge solutions for measuring tools and equipment, elevating the industry's standards in test and measurement capabilities within industrial automation systems.