Customer

The client, a leading Austrian-based provider of integrated hardware and software solutions for vehicle emission testing in the automotive industry, with a staff of more than 10,000 people and facilities in 45 countries worldwide, partnered with Applied Systems for this transformative project. International automotive manufacturers like Daimler, BMW, Mercedes, and others rely on the client's solutions to create new efficient engines.

Challenge

The client's primary product is a state-of-the-art automation system used for rig testing, ranging from the component testbed to the engine, powertrain, and vehicle testbed. This industrial test system supports different measuring device drivers, each of them equipped with its own flexible framework featuring ample implementation and configuration possibilities.

However, the existing application used to edit device drivers and define driver interfaces for the automation system faced challenges, impeding the client's ability to uphold their high standards of performance, usability, and innovation. The issues included inconsistent user experience hindering effective device driver creation, an outdated GUI design that was complex to understand and navigate, and difficulties in providing support for the application due to its extensive functionality.

Solution

Applied Systems was selected as the preferred partner based on its deep knowledge of GUI design and programming for measurement systems and its expertise in writing device drivers for industrial automation equipment. The client envisioned two guiding principles for the future solution:

1. Seamless user experience: The aim was to enhance usability and provide a consistent appearance throughout the application.

2. Standardization and unification: A single approach to developing drivers for different measuring devices and their components, encompassing error handling, scripts, and device abstraction layers, to expedite the development process and ensure quick support, thereby saving valuable time and resources.

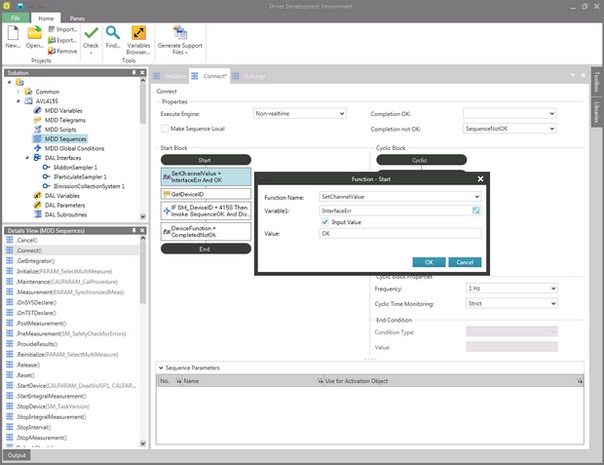

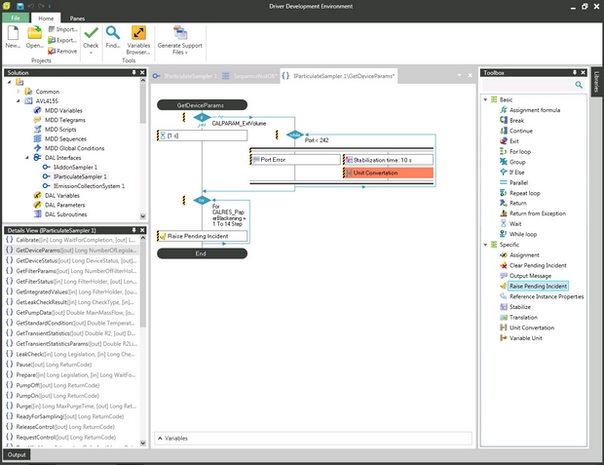

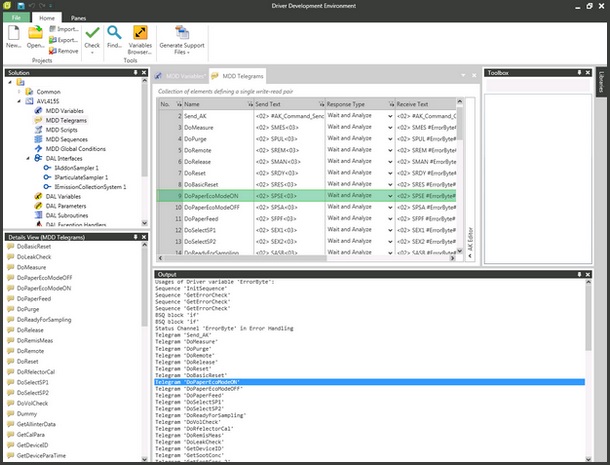

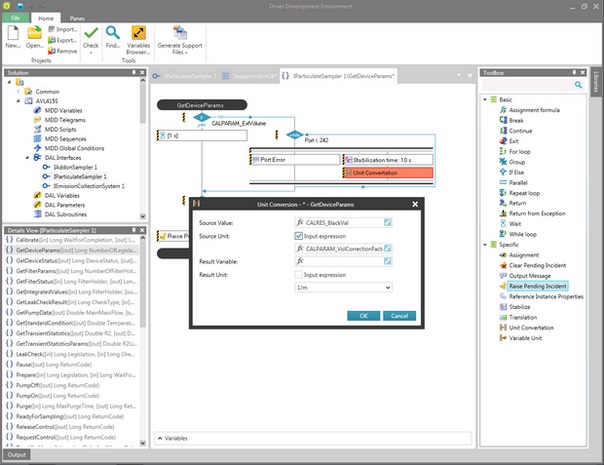

To materialize this vision, Applied Systems created the Driver Development Environment (DDE), a powerful application that simplifies the end-to-end process of creating drivers for test and measurement equipment used in industrial test systems. Leveraging abstract interfaces, device driver methods, procedures, variables, and error-handling components, DDE offered a comprehensive development environment.

Applied Systems' team meticulously handled all phases of the project, from requirements analysis to design, implementation, and quality assurance. Notably, they focused on enhancing usability through clickable prototypes to elaborate on user flow scenarios and define seamless interaction paths.

Technologies Employed: DDE was built using the .NET framework and WPF, ensuring a robust and user-friendly experience when working with industrial test systems and measuring devices. The use of Prism facilitated easy maintenance, allowing DDE to evolve over time. To ensure top-notch performance, automated regression and integration tests were deployed to guarantee comprehensive test coverage for all advanced scenarios, complex functionalities, and command combinations.

Collaboration with the Client: The project was executed by a dedicated team of five software developers and two QA engineers, working closely with the client using the Scrum framework. This agile approach enabled effective communication, swift responsiveness to emerging requirements, and quick adaptations to the product backlog.

Results

Applied Systems successfully completed the project, delivering a new and effective solution on time and within budget. The client and its customers now rely on DDE to seamlessly develop and integrate measuring devices into their industrial automation systems. The application substantially reduced device driver development time, thanks to the creation of libraries with ready-made device driver implementations.

Furthermore, DDE resolved the issue of providing accurate and rapid support for older versions of device drivers, a critical task in industrial test systems. The team introduced a simplified two-way migration, allowing new drivers to be converted to an older format and implementing new features into older drivers. This approach resulted in saving more than 50% of device driver development time.

Notably, the solution significantly improved the user experience with advanced features such as text highlighting, drag-and-drop functionality, and customization options. For instance, DDE enables users to save incorrect parametrization and promptly notifies them about error situations, offering a vast improvement compared to the previous version of the application.