Kunde

Der Kunde ist ein in Österreich ansässiger Hersteller von Motor-, Getriebe- und Emissionsprüfsystemen für Personenkraftwagen, Nutzfahrzeuge, Baumaschinen und Großmotoren und integriert diese in die Fahrzeuge.

Herausforderung

Der Kunde ist spezialisiert auf anspruchsvolle Produkte und Lösungen für die Automobilindustrie, wozu auch Emissionsprüfstände gehören, bei denen es sich um spezielle technische Mehrkomponentensysteme handelt. Diese aufwändigen und kostspieligen Ausrüstungen müssen konfiguriert werden, und jede verkaufte Anlage ist an die besonderen Anforderungen des jeweiligen Endkunden anzupassen.

Die manuelle Einrichtung individueller Konfigurationen ist sehr flexibel, umfasst aber jeweils mehr als 10.000 unterschiedliche Parameter. Die manuelle Durchführung einer solchen Konfiguration ist erstens zeitaufwändig und zweitens höchst fehleranfällig. Die Aufgabe bestand nun darin, ein Tool zu entwickeln, mit dem sich die Konfiguration für die gesteuerten Gerätschaften automatisch generieren und durchführen lässt.

Lösung

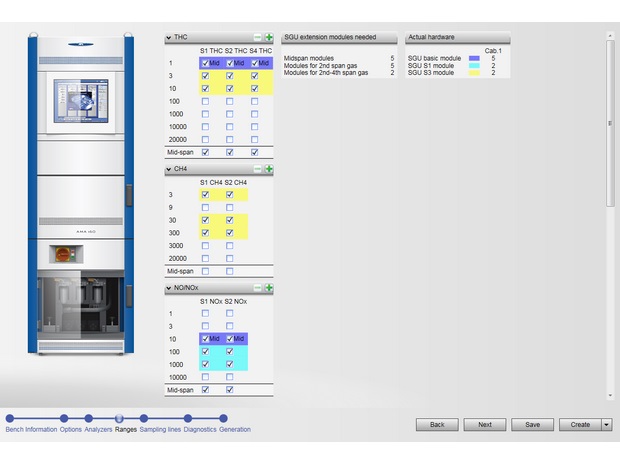

Die Idee war, einen Konfigurationsmanager zu entwickeln, der die meisten Parameter auf der Grundlage minimaler Eingangsdaten einstellt. Bei der Verwendung eines solchen Systems muss der Benutzer nur übergeordnete Daten eingeben, um die Anforderungen an die Hardwarekonfiguration zu formulieren.

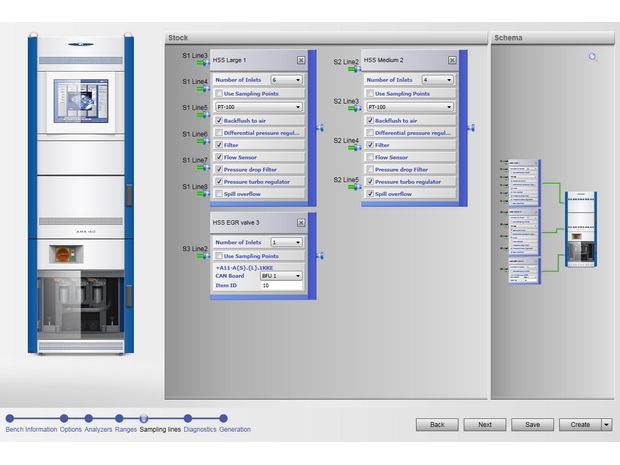

Um dieses Ziel zu erreichen, haben wir ein Programmmodell der Anlage definiert, das auf der Grundlage der Benutzereingaben eine komplette Konfiguration beschreibt. Um ein neues Modell zu erstellen, ist eine Reihe aufeinanderfolgender Schritte zur Beschreibung von Anwendungsbeispielen auf übergeordneter Ebene zu durchlaufen.

Mehr als 30 unabhängige Generierungsalgorithmen wandeln das definierte Programmmodell in den Dateiensatz für die Konfiguration der Zielhardware um. Jeder Algorithmus ist für eine spezielle Komponente der Konfiguration zuständig: die Erstellung von Gassystemen und elektrischen Leitungen, die Konfiguration der Prüfstandsumgebung, usw.

Der Konfigurationsmanager erstellt auch automatisch ganze Bereiche der Benutzeroberfläche: System-Dashboards für Bedienfelder des Prüfstands, interaktive Gasflussdiagramme, Servicebedienfelder für Analysegeräte, Druckregler, usw.

Zusätzlich zu den Generierungsalgorithmen implementiert das System eine Reihe von Validierungs- und Überprüfungsalgorithmen, um die erstellte Konfiguration auf ihre Richtigkeit zu kontrollieren.

Das Projekt wurde von Applied Systems in enger Abstimmung mit den Experten des Kunden entwickelt. Wir haben Interessenvertreter verschiedener Abteilungen in die Überprüfung der Spezifikationen einbezogen. Alle Anmerkungen und Korrekturen wurden sorgfältig gesammelt und in die Projektdokumentation aufgenommen.

Die erste stabile lauffähige Version der Software wurde in nur vier Monaten freigegeben. Das implementierte System verfügt über eine offene Architektur, sodass es heute mit den Ausrüstungs-Upgrades Schritt halten kann. Mit jeder Iteration lernt der Konfigurationsmanager mehr Anlagentypen und Erweiterungen hinzu.

Ergebnisse

Mit unserem System reduziert sich Ihr Aufwand bei der Erstellung der Anlagenkonfiguration ganz beträchtlich: eine durchschnittliche Konfiguration kann nunmehr in wenigen Stunden anstatt in mehreren Tagen abgeschlossen werden.

Der Konfigurationsmanager deckt etwa 90 % der Fälle ab, mit Ausnahme derjenigen, bei denen der Kunde seine Messtechnik an sehr spezielle Benutzeranforderungen anpasst.

Mit dem Konfigurationsmanager konnte der Flaschenhals in der Produktion beseitigt, die Produktwerbung am Markt beschleunigt und das Produktionsvolumen erhöht werden.